|

|

|

| |

SILKSCREEN MATERIALS |

|

| |

|

|

| |

|

|

| |

|

|

| |

SILKSCREEN EQUIPMENTS |

|

| |

|

|

| |

|

|

| |

|

|

| |

CERAMIC AUXILIARIES |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

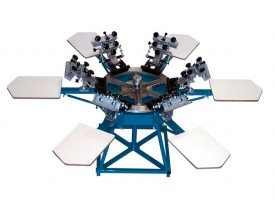

MANUAL PRINTER FOR T-SHIRT

Workhorse Original and Modular Textile Printers

|

| |

|

|

As the original tool-free adjustment printer, Workhorse printers stand the test of time as the professional?s choice for strength, durability and ease of use. Workhorse printers are ideal for growing and high-volume shops and those producing sophisticated designs. The large-diameter, full-length center shaft combined with print station support struts maximize strength. Precision machined cast aluminum print heads and print wheel combined with tapered roller bearings make high production manual.

DOWNLOADS : Product Brochure |

|

| |

| Performance Features |

W44M

W44A |

W60

|

W66M

W66A |

W860

|

W860

W88A |

W860 |

Number of Jobs/ Complexity of Design |

GOOD |

BETTER |

BETTER |

BEST |

BEST |

BEST |

Production Speed |

BETTER |

BEST |

BEST |

BEST |

BEST |

BEST |

Ease / Speed of Set-up |

BETTER |

BEST |

BEST |

BEST |

BEST |

BEST |

|

| |

| |

| PRODUCT FEATURES |

| Precision Machined, Cast Aluminum Print Heads and Print Wheel |

|

Large Diameter, Full Length Center Shaft with Tapered Bearings |

| Print Station Support Struts |

|

Tool-Free Adjustments |

| Dial-In Off Contact |

|

Micro-Adjust Screen Angle |

| Super Responsive Micro Registration |

|

Bearing-Aided Micro Cinch- Down/Anti-Droop |

| Extra Large Diameter Registration Points |

|

Large Screen Capacity |

Easy to Load, Quick Change Pallets

|

|

Upgradeable - 4 Color 4 Station to 6 Color 4 Station, 6 Color 6 Station to 8 Color 6 Station |

Options: Side Clamps, Additional Print Heads

|

|

|

|

|

|

PART |

DESCRIPTION |

10005 |

WORKHORSE MODULAR W44M, 4 COLOR, 4 STATION 32? MAX SCREEN WIDTH (EXPANDABLE TO 6 COLOR 4 STATION)

|

10007 |

WORKHORSE MODULAR W66M, 6 COLOR, 6 STATION 26? MAX SCREEN WIDTH (EXPANDABLE TO 8 COLOR 6 STATION)

|

10222 |

WORKHORSE ADD-ON PRINT HEAD UPGRADE (FITS ONLY WORKHORSE MODULAR 4-4 AND 6-6)

|

10011 |

WORKHORSE ORIGINAL W64O, 6 COLOR, 4 STATION 23? MAX SCREEN WIDTH

|

10010 |

WORKHORSE ORIGINAL W86O, 8 COLOR, 6 STATION 21? MAX SCREEN WIDTH

|

10009 |

WORKHORSE ORIGINAL W88O, 8 COLOR, 8 STATION 26? MAX SCREEN WIDTH

|

10012 |

WORKHORSE ORIGINAL W108O, 10 COLOR, 8 STATION, 23? MAX SCREEN WIDTH

|

12601 |

SIDE CLAMP UPGRADE 26" (PRICE PER COLOR WHEN SUBSTITUTED FOR BACK CLAMPS)

|

12596 |

SIDE CLAMP UPGRADE 23" (PRICE PER COLOR WHEN SUBSTITUTED FOR BACK CLAMPS)

|

|

| |

| |

|

DRYER FOR T-SHIRT

Powerhouse Infrared / Convection Drying System

|

| |

|

|

In contrast to competitive dryers which offer only narrow belts and minimal wattage, Powerhouse?s wider belt widths and more powerful ovens let you achieve maximum production rates. Plus with a flip of the switch, Flash Phase speeds production by raising garment and ink temperatures more quickly. Flash Phase fully powers the first heat zone while the remaining heat zone is controlled by the digital temperature control. |

|

Powerhouse?s medium wave IR elements transmit heat more quickly than conventional ceramic panels and turbo air-knives turn quick-curing IR heat into gentle convection heat for curing bulky items such as sweat shirts and jackets. Heated air recovery draws preheated air from beneath the belt and returns it to the oven area for energy efficiency Adjustable oven doors help retain oven temperature.

Additionally, the removable oven hood provides easy access to the interior oven for regular cleaning. 4-point belt tracking makes it easy to set up your dryer and extends belt life. Optional add-on in-feed and out-feed facilitates garment loading and unloading when running multiple printing machines.

DOWNLOADS : Product Brochure

|

| |

| Performance Features |

PQ / PC2608 |

PQ3011

|

PQ4013 |

PQ5217 |

Ease of Loading Garments: |

BETTER |

BETTER |

BEST |

BEST |

Curing Capacity: |

BETTER |

BETTER |

BEST |

BEST |

Curing Control: |

BEST |

BEST |

BEST |

BEST |

|

| |

|

|

|

PART |

ESCRIPTION |

POWER |

11212 |

POWERHOUSE QUARTZ PQ2608, CONVEYOR DRYER 26"x08' |

220V, 1 Phase, 50-60Hz, 8400Watts, 50Amps

|

11263 |

POWERHOUSE CERAMIC PANEL

PC2408, CONVEYOR DRYER 26"x08" |

220V, 1 Phase, 50-60Hz, 7200Watts, 43Amps |

20934 |

CAP ELEMENT OPTION CEO, 2500Watts |

220V, 1 Phase, 50-60Hz, 2500Watts, 11Amps |

11226 |

POWERHOUSE QUARTZ PQ3011, CONVEYOR DRYER 30"X11" |

220-240V, 1 Phase, 50-60Hz, 12000 Watts,56Amps |

11227 |

POWERHOUSE QUARTZ PQ3011, ONVEYOR DRYER 30"X11" |

220-240V, 3 Phase, 50-60Hz, 12000 Watts,38Amps |

11231 |

POWERHOUSE 30, INFEED/EXIT 3 EXTENSION |

|

11263 |

POWERHOUSE QUARTZ PQ4013, CONVEYOR DRYER 40"X13" |

220-240V, 1 Phase, 50-60Hz, 18000 Watts,82Amps |

11236 |

POWERHOUSE QUARTZ PQ4013,

CONVEYOR DRYER "40X13" |

220-240V, 3 Phase, 50-60Hz, 18000 Watts,56Amps |

11226 |

POWERHOUSE 40, INFEED/EXIT 3

EXTENSION |

|

11227 |

POWERHOUSE QUARTZ PQ5217, CONVEYOR DRYER 52"X17" |

220-240V, 3 Phase, 50-60Hz, 30600 Watts,91Amps

|

11231 |

POWERHOUSE 52, INFEED/EXIT 3 (.9m) EXTENSION |

|

| |

| |

|

FLASH CURE FOR T-SHIRT

| |

|

|

Whether you choose the Primus Manual or Primus Automatic Flash Curing Unit, the Extra Large heat panel cures larger images evenly while the Air-Cooled Heat Shield keeps your shop cool and safe. Primus Automatic automatically rotates onto and off of the pallet. The foot-switch activated dwell timer provides exacting control of your flash curing time. Primus Automatic can be operated in automatic or manual modes.

DOWNLOADS : Product Brochure |

|

| |

| Performance Features |

P1820M

115vac |

P1820A

115vac |

P1820M

230vac |

P1820A

230vac |

Size of Printing Image |

BEST |

BEST |

BEST |

BEST |

Flash Curing Speed |

BETTER |

BETTER |

BEST |

BEST |

Flash Curing Time Control |

GOOD |

BETTER |

GOOD |

BEST |

|

| |

| PART |

ESCRIPTION |

POWER |

| 11000 |

PRIMUS P1820M, Manual Flash Cure,

18X20" (46x51cm)

|

115VAC, 50-60Hz, 1969Watts, 18Amps

|

| 11001 |

PRIMUS P1820M, Manual Flash Cure,

18X20" (46x51cm)

|

230VAC , 50-60Hz, 3034Watts 14Amps |

| 11102 |

PRIMUS, Automatic Rotation Upgrade,

115VAC

|

115VAC, 50-60Hz, 2Amps |

| 11103 |

PRIMUS, Automatic Rotation

Upgrade, 230VAC

|

230VAC, 50-60Hz, 1Amps |

| 11100 |

PRIMUS P1820A, Automatic

Flash Cure, 18X20" (46x51cm)s

|

115VAC, 50-60Hz, 2199Watts, 20Amps |

| 11101 |

PRIMUS P1820A, Automatic

Flash Cure, 18X20" (46x51cm) |

230VAC, 50-60Hz, 3250Watts, 15Amps |

|

| |

| |

|

CAP PRINTER

|

|

CapMax cap printing system is the ultimate cap printing system capable of printing from simple to the most extreme designs on the widest variety of caps, including 6 panel caps. CapMax uses a curved platen and screen that follow the natural shape of the cap. CapMax is available in four configurations. The CMM44 comes standard with both Cap and T-Shirt pallets making it a dual purpose Cap and TShirt printer. CapMax bench models include CMM11, 1 Color 1 Station, CMM21, 2 Color 1 Station, and CMM41, 4 Color 1 Station. Each includes a 110 Mesh Screen(s), Squeegee(s) and CP2 Platen(s).

DOWNLOADS : Product Brochure |

|

| |

|

| |

| |

| PRODUCT FEATURES |

| Convex Screen and Platen System |

|

Large Diameter Center Shaft with Tapered Bearings |

| Sturdy Tubular Steel Construction |

|

Fine Thread Micro Registration |

| Adjustable Off-Contact |

|

Adjustable Screen Angle |

| Large Diameter Registration Points |

|

Upgradeable 4 Color 4 Station to 6 Color 6 Station, 2 Color 1 Station to 4 Color 1 Station |

| Options?Additional Print Heads and Print Stations |

|

|

|

|

|

|

PART |

DESCRIPTION |

10204 |

CAPMAX CMM11, 1 COLOR / 1 STATION BENCH MODEL CAP PRINTER

|

10203 |

CAPMAX CMM21, 2 COLOR / 1 STATION BENCH MODEL CAP PRINTER

|

10201 |

CAPMAX CMM41, 4 COLOR / 1 STATION BENCH MODEL W/ MICRO REG.

|

10202 |

CAPMAX CMM44, 4 COLOR / 4 STATION DUAL PURPOSE CAP AND T-SHIRT PRINTER |

|

| |

| |

|

|