|

|

|

|

|

| |

SILKSCREEN MATERIALS |

|

| |

|

|

| |

|

|

| |

|

|

| |

SILKSCREEN EQUIPMENTS |

|

| |

|

|

| |

|

|

| |

|

|

| |

CERAMIC AUXILIARIES |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

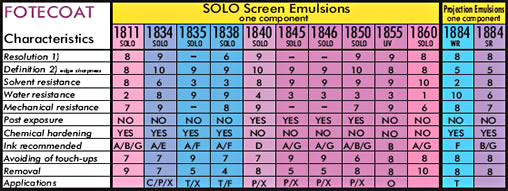

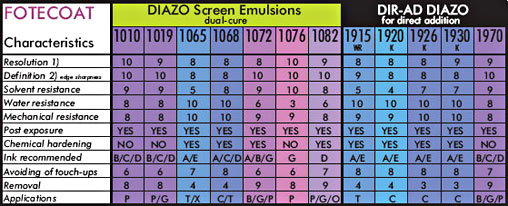

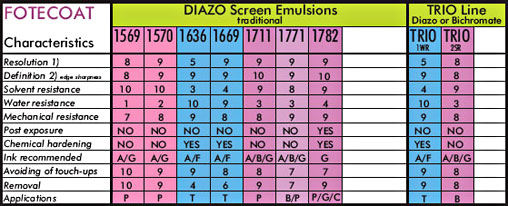

PHOTOEMULSION & SCREEN CHEMICALS |

Fotecoat - Information Chart

Screen Emulsions and their technical characteristics

|

|

|

|

| |

|

| |

|

| LEGEND: |

1) on yellow fabric under ideal conditions

2) with adequate coating technique on corresponding mesh |

| |

|

| Inks: |

A) Plastisols, B) Standard UV, C) Aqueous UV, D) Solvent/Water,

E) Water/Solvent, F) Water only, G) Solvent only, H) Most inks for short runs,

I) Universal |

| |

|

| Applications: |

B) Bottles, C) Ceramic, F) Food, G) Glass, P) Printed Circuits, T) Textile,

X) Thick Stencils |

| |

|

| Tints: (in %) |

|

solvent

resistant |

|

water

resistant |

|

co-solvent

resistant |

|

|

| |

|

FOTECHEM Check-Chart

- These chemicals for the stencil production are of Swiss origin

- All products mentioned on this sheet are for industrial use only.

- You will find "how to use" instructions for most products on the label of the can, and as TECHNICAL INFORMATIONS

- Where necessary the risk and safety phrases are printed on the labels of the product.

- Safety Data Sheets available on request

|

|

Legend : * = suitable for automatic machines

= recommended = recommended

= not recommended = not recommended

| |

= concentrate (use reduced only) |

|

| |

|

|

|

|

|

|